A big problem appeared when I tried to build the instruments as realistic as possible. Where could a normal

person get in Europe exact pictures and drawings of the F-16`s instruments? I had to search for a long time

and right now I do not have all the informations I would like to have. Even though, using different help and

information. I was able to build the instruments quite realistic.

I had following information sources:

- pictures which I count take at the ILA (see pictures of ILA)

- drawings and pictures from the "LOCK ON No 2" magazine (ISBN 90-70932-03-2)

- pictures of the "Walk Around F-16 Fighting Falcon" (ISBN 0-89747-307-8)

- a cockpit model of the F-16 Block A 1:12 (ESCI Models)

Based on these informations I could get relative precise data about the instruments. As the different

instruments are built to be interchangeable, the size of one instrument could provide the dimensions of

another. Even though some compromises had to be made, as the FLCS and the Throttle of

Thrustmaster take more space and therefor panels placed

near the controls have less space.

All instruments with switches/buttons - which I will call

"panels" in future,

are black-painted, and manufactured from1.5mm aluminum plate disks. The labels

consist of white "Rubbel" letters, which are used for labels of circuit boards

etc. The necessary switches, buttons and rotary knobs do not unfortunately always

resemble the originals. The rotary knobs were painted uniformly in grey (specifically

ACRYL resin spray " TS32 - HAZE GREY " of the company Tamiya, available in all

good model construction specialist shops). Original switches and buttons have the

company

EHC.

So far I like my panels quite good, but they still have a problem: they have not back-lighting, which is a big

handicap during night flights, as far as you don't want to use any spotlight or candles inside your cockpit ;-).

Therefore I have been designing new cheap but still realistic panels. So far I have experimented with

different materials like glass, plastic and now I have finally a solution that comes close to the real thing.

This design has the advantage, that the panels can be mounted on a metal basis. How are these special panels

built?

A black painted metall plate serves as basis for the switches to be installed. This plate is strong enough to

resist even extreme handling of the switches.

Onto the metal base a 5 mm acryl panel is screwed on. This is done from the bottom. The acryl panel has the

according drillings to hold the switches or required elements. The panel is painted with black enamel. The

labels are done by laser-burning and have a depth of about 1 mm. Another way is to engrave the labels with a

computerised engraver. There are many places where this labeling can be done.

The lighting is achieved by several LED, which are installed at the backside with a depth of about 4 mm.

Lighting can be done using different LED colors (yellow, green or just white). The advantage of using LEDs is

that they are cheap, do not produce heat and require low ampere. Normally about 4 LEDs would be enough to

light any panel. The panels I saw, had a white light green shaded illumination. The advantage of using LEDs

instead of 5V light bulbs is obvious. LEDs are cheap, do not produce heat and require only low amperes. If you

have about 50 panels, these are facts to be considered.

Connection is easily made using connectors at the lower side. One connector is used to power the LEDs and

another is used for powering the switches.

The panels are mounted onto the metal base using M4x4 metal screws. The original panels use bayonet screws,

but they are difficult to get. By the way the drilling for fitting the panels is 9,54 mm.

|

Procedure

|

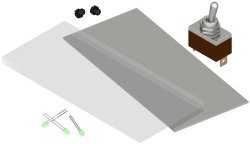

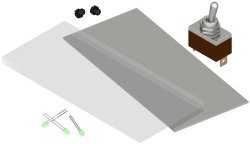

The basic panels...

|

...are drilled...

|

...black paint...

|

...labeling (laser or engraving).

|

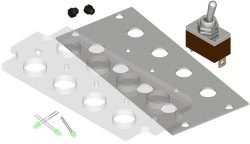

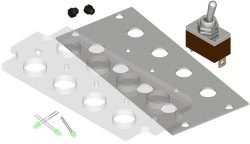

Fitting on the metal base...

|

...and ready!

|

Here with the corresponding screws

|

Diagram

|

The instruments with displays (e.g. ALTO -, HSI or AOA displays) - I will call

in future

"displays" - consists of 3mm acrylic glass, which - with appropriate

marks taken off - were painted black (color spray "black silk matt" of the company

SPRAY COLOR). The displays are mockups from 1mm pasteboard, which - with prints

colored and cut out - were stuck one above the other in several layers, e.g. a

layer background, a layer of small pointers, a layer of large pointers, etc. Genuine

instruments were too expensive for me, and are likewise connected to the computer

only at immense expense.

I have been asked many times, how I have installed the warning-lights on the glare-shield. Well in some

electronic shops (here in Germany

Conrad-Electronik for example) have square

lights of about 18 x 18 mm and 24 x 18mm (for the master caution). Normaly they are sold with 4 covers, each a

different color (yellow, green ,red and white). The light bulb that is included requires 24 VDC and can be

replaced by a LED. The label is made wit a CAD program and printed on plastic foil. The powering of the

warning lights is done by the

32 point output modul of the EPIC card.

That simple.

The instruments with displays (e.g. ALTO -, HSI or AOA displays) - I will call

in future "displays" - consists of 3mm acrylic glass, which - with appropriate

marks taken off - were painted black (color spray "black silk matt" of the company

SPRAY COLOR). The displays are mockups from 1mm pasteboard, which - with prints

colored and cut out - were stuck one above the other in several layers, e.g. a

layer background, a layer of small pointers, a layer of large pointers, etc. Genuine

instruments were too expensive for me, and are likewise connected to the computer

only at immense expense.

The instruments with displays (e.g. ALTO -, HSI or AOA displays) - I will call

in future "displays" - consists of 3mm acrylic glass, which - with appropriate

marks taken off - were painted black (color spray "black silk matt" of the company

SPRAY COLOR). The displays are mockups from 1mm pasteboard, which - with prints

colored and cut out - were stuck one above the other in several layers, e.g. a

layer background, a layer of small pointers, a layer of large pointers, etc. Genuine

instruments were too expensive for me, and are likewise connected to the computer

only at immense expense.

I have been asked many times, how I have installed the warning-lights on the glare-shield. Well in some

electronic shops (here in Germany Conrad-Electronik for example) have square

lights of about 18 x 18 mm and 24 x 18mm (for the master caution). Normaly they are sold with 4 covers, each a

different color (yellow, green ,red and white). The light bulb that is included requires 24 VDC and can be

replaced by a LED. The label is made wit a CAD program and printed on plastic foil. The powering of the

warning lights is done by the 32 point output modul of the EPIC card.

That simple.

I have been asked many times, how I have installed the warning-lights on the glare-shield. Well in some

electronic shops (here in Germany Conrad-Electronik for example) have square

lights of about 18 x 18 mm and 24 x 18mm (for the master caution). Normaly they are sold with 4 covers, each a

different color (yellow, green ,red and white). The light bulb that is included requires 24 VDC and can be

replaced by a LED. The label is made wit a CAD program and printed on plastic foil. The powering of the

warning lights is done by the 32 point output modul of the EPIC card.

That simple.